Our stainless steel cans are made of high-quality stainless steel, meeting food-grade sanitary standards, and are suitable for food processing, beverage production, pharmaceutical, and chemical industries. The product features corrosion resistance, high-temperature tolerance, and easy cleaning, ensuring the safety and hygiene of liquid or material storage. Whether for small containers or large storage tanks, we provide high-quality solutions.

The hot and cold tank (also known as an aging tank) offers advantages such as energy efficiency, noise reduction, corrosion resistance, strong production capacity, and easy cleaning. It is widely used in industries such as dairy, food, pharmaceuticals, chemicals, and beverages. As essential equipment for heating, cooling, insulation, sterilization, or slurry storage, it is particularly suitable for pasteurization and insulation of milk, making it a necessary component in ice cream production lines.

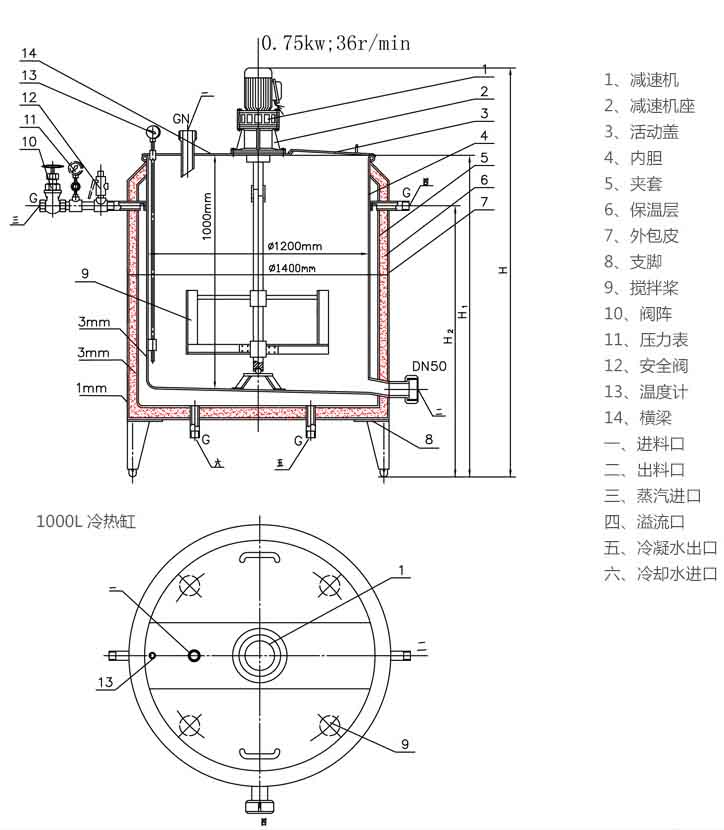

This equipment consists of an inner liner, jacket, insulation layer, outer casing, reducer, stirring paddle, and thermometer.

Inner Liner: Made of stainless steel 304, with a polished surface.

Middle Jacket: Constructed from A3 steel or 1Cr18Ni9Ti steel, featuring a reinforced spiral design. Cold water flows from bottom to top (without pressure) to achieve optimal heating and cooling performance.

Insulation Group: Formed from stainless steel plates with a fish-scale pattern, the insulation layer uses polyurethane or glass wool to maintain temperature against the external environment, achieving effective insulation.

Reducer: A cycloidal pinwheel planetary reducer, fixed on a bracket in the beam. The reducer’s output shaft connects to the stirring paddle via a loose coupling, facilitating easy disassembly and cleaning.

Thermometer: Specification 0°C to 1000°C, installed on the beam and extending to the lowest medium position. It ensures temperature monitoring even at the minimum liquid level, supporting sterilization and aging processes.

Below is the English translation of the provided text, formatted for easy copying and use on your website:

| Specification | 100L | 200L | 300L | 600L | 1000L | 2000L | 3000L | 4000L | 5000L |

|---|---|---|---|---|---|---|---|---|---|

| Heating Area (㎡) | 0.7 | 1.1 | 1.6 | 2.5 | 4.5 | 7.5 | 8.5 | 10.5 | 13.3 |

| Motor Power (kW) | 0.37 | 0.37 | 0.55 | 0.75 | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 |

| Nominal Capacity (L) | 100 | 200 | 300 | 600 | 1000 | 2000 | 3000 | 4000 | 5000 |

| Material Inlet/Outlet (DN) | 40 | 40 | 40 | 40 | 40 | 50 | 50 | 50 | 50 |

| Working Temperature | Jacket: <138℃, Inner Tank: <100℃ | ||||||||

| Working Pressure (MPa) | Jacket: 0.08-0.3, Inner Tank: 0.09 | ||||||||

| Test Pressure (MPa) | 0.15 | ||||||||

| Jacket Pressure (MPa) | 0.09 | ||||||||

| Stirrer Speed (r/min) | 36 (Customizable speeds: 17, 32, 48, 60, 82, 127, 155, or stepless/variable frequency speed control) | ||||||||

| Inner Layer Thickness (mm) | 3 | ||||||||

| Jacket Thickness (mm) | 3 | ||||||||

| Outer Layer Thickness (mm) | 0.6 | ||||||||

| Insulation Layer | Asbestos insulation layer | ||||||||

| Basic Accessories | Thermometer, safety valve, pressure gauge | ||||||||

| Container Category | Classified as normal pressure vessel or Class I pressure vessel based on design pressure and medium characteristics | ||||||||

| Material | Inner Tank: Stainless Steel SUS304/SUS316L; Jacket: SUS304/Q235-B; Outer Casing: SUS304 |

Note: The stirring motor power in the table is for reference only. The motor power, stirring speed, and paddle type depend on the material properties.

By Heating Medium:

Natural Gas Hot and Cold Tank

Steam Hot and Cold Tank

Electric Heating Hot and Cold Tank

By Material Inlet/Outlet:

Open-Type Hot and Cold Tank

Sealed-Type Hot and Cold Tank

By Structure:

Standard Type

Upper and Lower Conical Type

Upper and Lower Head Type

Adjust the equipment’s legs to ensure it is level and the reducer is vertical before installing pipelines. During operation, ensure the stirring paddle rotates clockwise and does not reverse.

Instructions: Before use, clean the tank with warm water and disinfect it with steam. Material slurry enters via the material pipe on the lid or by opening the lid. Avoid overfilling to prevent splashing during stirring, which could lead to unhygienic conditions or material loss.

Heating Method: Close the refrigerant inlet valve, drain any remaining refrigerant from the jacket, add material, start the stirrer, then open the steam valve. Once the desired temperature is reached, close the steam valve first, wait 2-3 minutes, then stop the stirrer.

Cooling Method: Close the steam valve, drain the remaining steam condensate from the jacket, then open the refrigerant valve at the tank bottom to allow refrigerant to pass through the jacket, reducing the material temperature inside.

Insulation: Adjust the stirrer and valve speed based on the desired temperature (monitor the thermometer) to maintain insulation effectively.

Cleaning: After processing, drain any remaining condensate from the jacket, rinse with warm water as soon as possible to remove sticky materials, then clean the inner walls thoroughly with 40°C-50°C alkaline water, followed by a clear water rinse. For the next use, disinfect with hot water or steam (above 90°C) for 2-3 minutes.

Maintenance: Regularly check the equipment and reducer’s operation. Replenish reducer lubricant if insufficient, and change the oil (40# machine oil) every six months. When not in use, rinse the jacket with warm water to prevent saltwater corrosion, and regularly clean the tank body to keep the exterior clean and the inner liner shiny for durability.

Pressure Gauge

Safety Valve

Steam Inlet Gate Valve

Thermometer

Contact: Mr. Kingsley Ma

Phone: 13037600603

Tel: 0371-63752708

Email: [email protected]

Add: No. 316, Lianhua Street, Zhengzhou, Henan, China