The Stainless Steel Mixing Tank (Preparation Tank, Formulation Tank) is a high-quality industrial equipment widely used in pharmaceutical, food, and chemical industries for liquid mixing, preparation, and storage. Made from premium stainless steel, it offers corrosion resistance, high-temperature endurance, and easy cleaning, ensuring a safe and hygienic production process. The equipment is designed with flexibility, allowing customization of capacity and functions to meet various industrial application needs.

产品简介:

调配罐又称配制罐,浓稀配液罐,配罐抖料缸,混料缸,调配罐。清洗方便、结构简单等特点,用于乳品和食粮及其他元素和药物再配件后进行搅拌均匀作用。不锈钢搅拌罐广泛应用于涂料、医药、建材、化工、颜料、树脂、食品、科研等行业。可根据用户产品的工艺要求选用

304、316L材料制作,以及设置加热、冷却装置,以满足不同的工艺和生产需要.加热形式有夹套加热、盘管加热,该设备结构合理、工艺先进

、经久耐用,并具有操作简单,使用方便等特点,是理想的投资少、投产快、收益高的化工设备。

Concentrated/Dilute Mixing Tank (Blending Tank/Stirring Tank)

The concentrated/dilute mixing tank (blending tank/stirring tank) is generally a vertical mixing vessel designed to blend materials through stirring operations to meet the requirements of the production process.

Structure and Features:

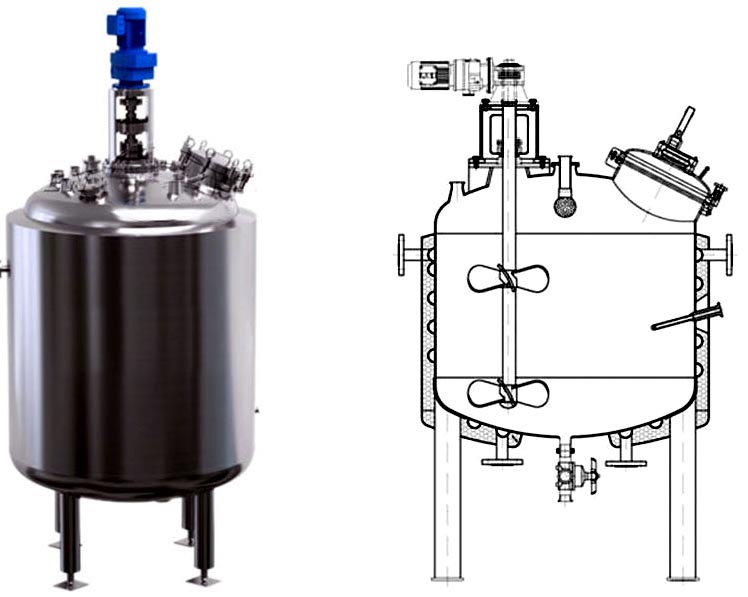

The tank adopts a vertical cylindrical body, customizable according to customer requirements.

Optional features include a jacket, coil, or insulation layer (supporting heating, cooling, or heat preservation).

Made of high-quality 316L or 304 stainless steel.

The inner surface is treated with electrolytic mirror polishing or mechanical polishing.

The outer surface features a 304 fully welded insulation structure, finished with a mirror or matte treatment.

All inlet/outlet ports and welds with the inner tank body utilize flanged arc transitions, ensuring smooth, easy-to-clean surfaces with no dead corners and an aesthetically pleasing appearance.

Customization Options:

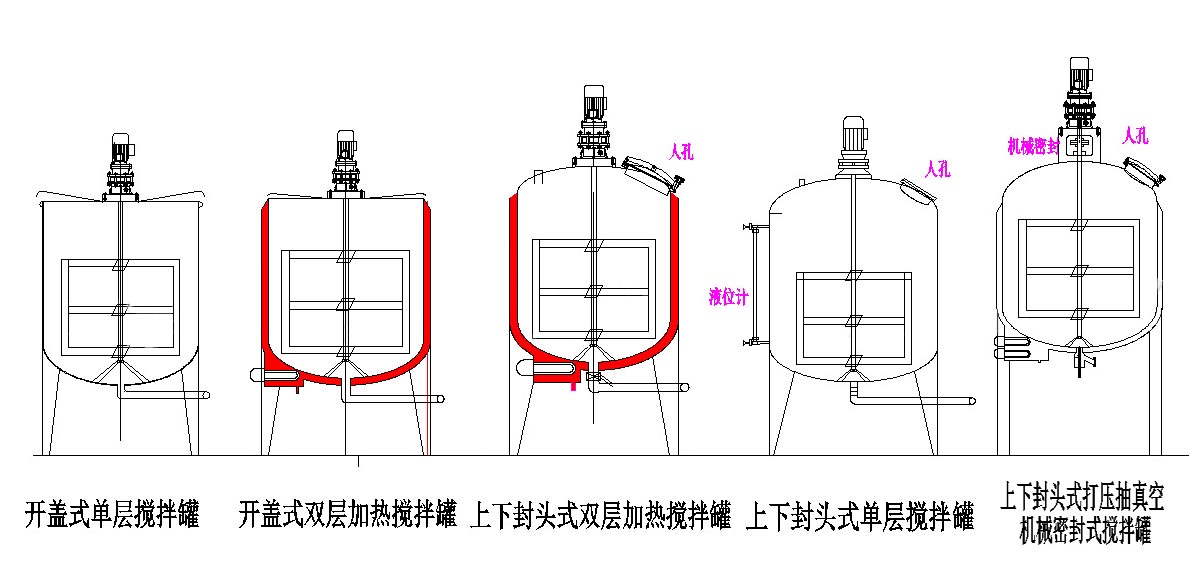

The mixing tank can be designed as single-layer, double-layer (with an insulation layer on the tank body and bottom head), or jacketed (with a jacket and insulation layer on the tank body and bottom head).

Available in vertical or horizontal structures.

Based on customer requirements, the tank can be crafted into various shapes such as square or round, equipped with mechanical stirring and optional components.

Concentrated/Dilute Mixing Tank Optional Configurations:

The tank body can be equipped with the following optional features, or configured according to customer requirements:

Sterile air filter

Thermometer (digital display or dial type)

pH meter

Pressure gauge

Steam sterilization port

Sight glass

Sanitary manhole

Liquid inlet/outlet ports

CIP universal rotating cleaning ball

Liquid level gauge and automatic liquid level control system (load-bearing module, non-contact ultrasonic, or static pressure transmitter)

The tank can be used as a storage tank, mixing tank, temporary storage tank, or blending tank, suitable for liquid material mixing and storage in industries such as:

Traditional Chinese medicine

Food

Juice beverages

Dairy products

Seasonings

Brewing

Beer

Pharmaceuticals

Chemicals

Bioengineering

Capacity: Available in various specifications from 100L to 5000L, designed and manufactured based on customers’ actual needs.

Connections: Quick-clamp (chuck) interface design; the inner liner is made of 304 or 316L stainless steel, with a mirror-polished inner surface (Ra ≤ 0.28μm–0.6μm). The outer surface can be polished, brushed, or sandblasted according to customer requirements.

Customization: Depending on production and process requirements, the tank can be designed with:

Heating or cooling systems

Low- or high-speed mixing systems

Sealed pressure systems

Vacuum systems

Metering systems

Mixing Paddle Design: The structure of the mixing paddle can be adjusted to suit different materials and desired mixing effects, with options including turbine, paddle, anchor, frame, or ribbon types.

| 型号 | 规格L | 参考尺寸 | 搅拌转速 (r/min) | 工作压力 | 工作温度 | |||

筒体直径 (mm) ) | 筒体高度 (mm) | H1(出料口距地) | 功率 | 36 转/分 (可根据客户使用情况进行调整设计) | ≤0.09MPa ( 常压 ) | < 160 ℃ | ||

| JBG01-50 | 50 | 400 | 400 | 300 | 0.37 | |||

| JBG01-100 | 100 | 500 | 500 | 300 | 0.37 | |||

| JBG01-150 | 150 | 600 | 500 | 300 | 0.37 | |||

| JBG01-250 | 250 | 600 | 800 | 300 | 0.55 | |||

| JBG01-300 | 300 | 700 | 800 | 300 | 0.55 | |||

| JBG01-500 | 500 | 800 | 950 | 300 | 0.55 | |||

| JBG01-600 | 600 | 900 | 950 | 300 | 0.55 | |||

| JBG01-1000 | 1000 | 1000 | 1200 | 300 | 0.75 | |||

JBG01-1200 | 1200 | 1100 | 1200 | 300 | 0.75 | |||

JBG01-1500 | 1500 | 1200 | 1200 | 300 | 0.75 | |||

JBG01-2000 | 2000 | 1200 | 1500 | 350 | 1.5 | |||

JBG01-2500 | 2500 | 1400 | 1500 | 350 | 1.5 | |||

JBG01-3000 | 3000 | 1500 | 1500 | 350 | 2.2 | |||

JBG01-4000 | 4000 | 1600 | 1800 | 350 | 4 | |||

可选搅拌

可选组件

Contact: Mr. Kingsley Ma

Phone: 13037600603

Tel: 0371-63752708

Email: [email protected]

Add: No. 316, Lianhua Street, Zhengzhou, Henan, China