Our stainless steel liquid storage tank (sanitary storage tank) is made of high-quality stainless steel, meeting food-grade sanitary standards. It is widely used in industries such as food, pharmaceutical, and chemical. The product features corrosion resistance, high-temperature resistance, and easy cleaning, ensuring the safety and hygiene of liquid storage. Whether for industrial use or sensitive material storage, our tanks provide a reliable solution.

This series of stainless steel storage tanks consists of single-layer, vertical sanitary container equipment. It serves as intermediate buffer and liquid storage equipment in industries such as pharmaceuticals, biotechnology, engineering, food, beverages, fruit wine, seasonings, chemicals, and oils.

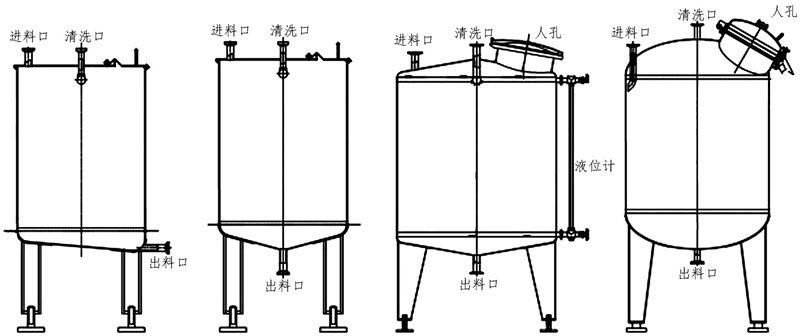

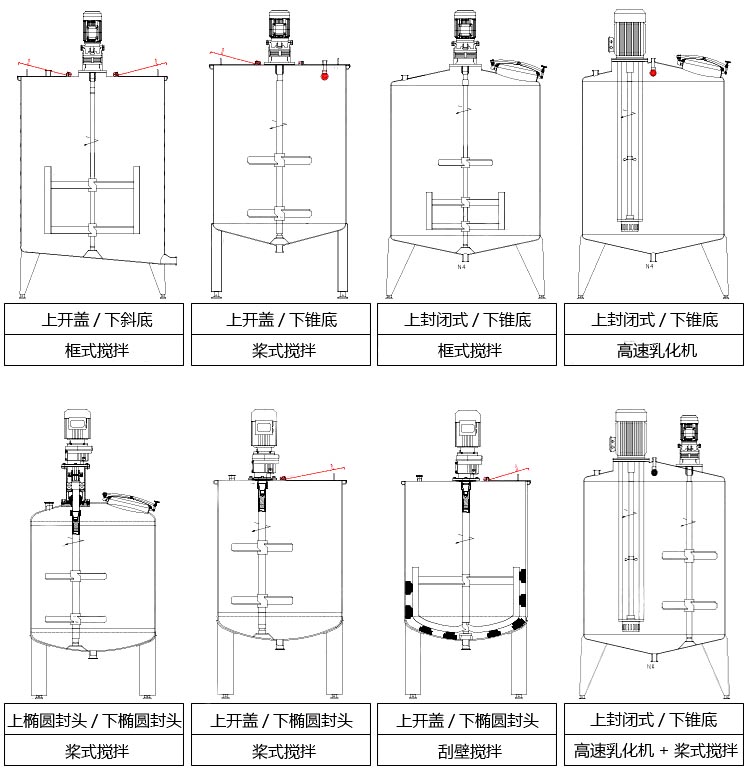

By Structural Form:

Top open cover with slanted bottom

Top open cover with conical head bottom

Upper and lower conical heads

Upper and lower elliptical heads

By Material:

SUS304

SUS316L

This series of storage tanks features a cylindrical stainless steel inner body, equipped with a sanitary manhole, cleaning ball, and liquid level gauge.

Equipment Structure:

Single-layer structure. The inner wall of the tank adopts arc transitions in the filtration section, ensuring no sanitary dead corners and easy cleaning. The interior is mirror-polished to enable CIP (Clean-in-Place) and SIP (Sterilize-in-Place), meeting sanitary standard requirements.

Material:

Stainless steel SUS304 or SUS316L

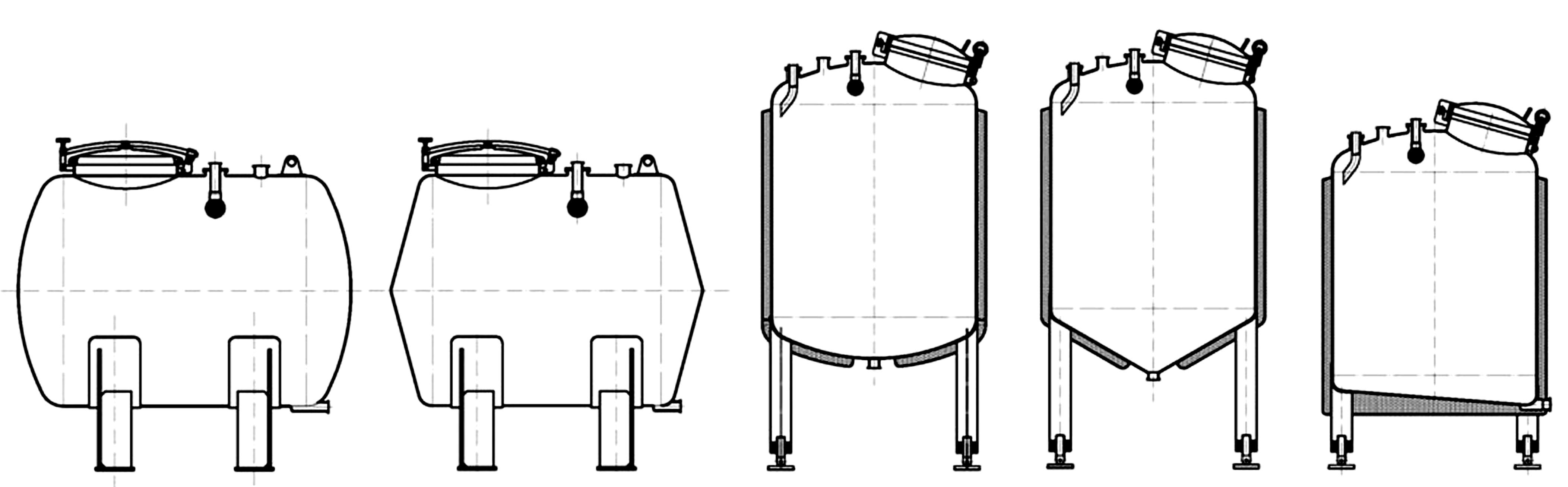

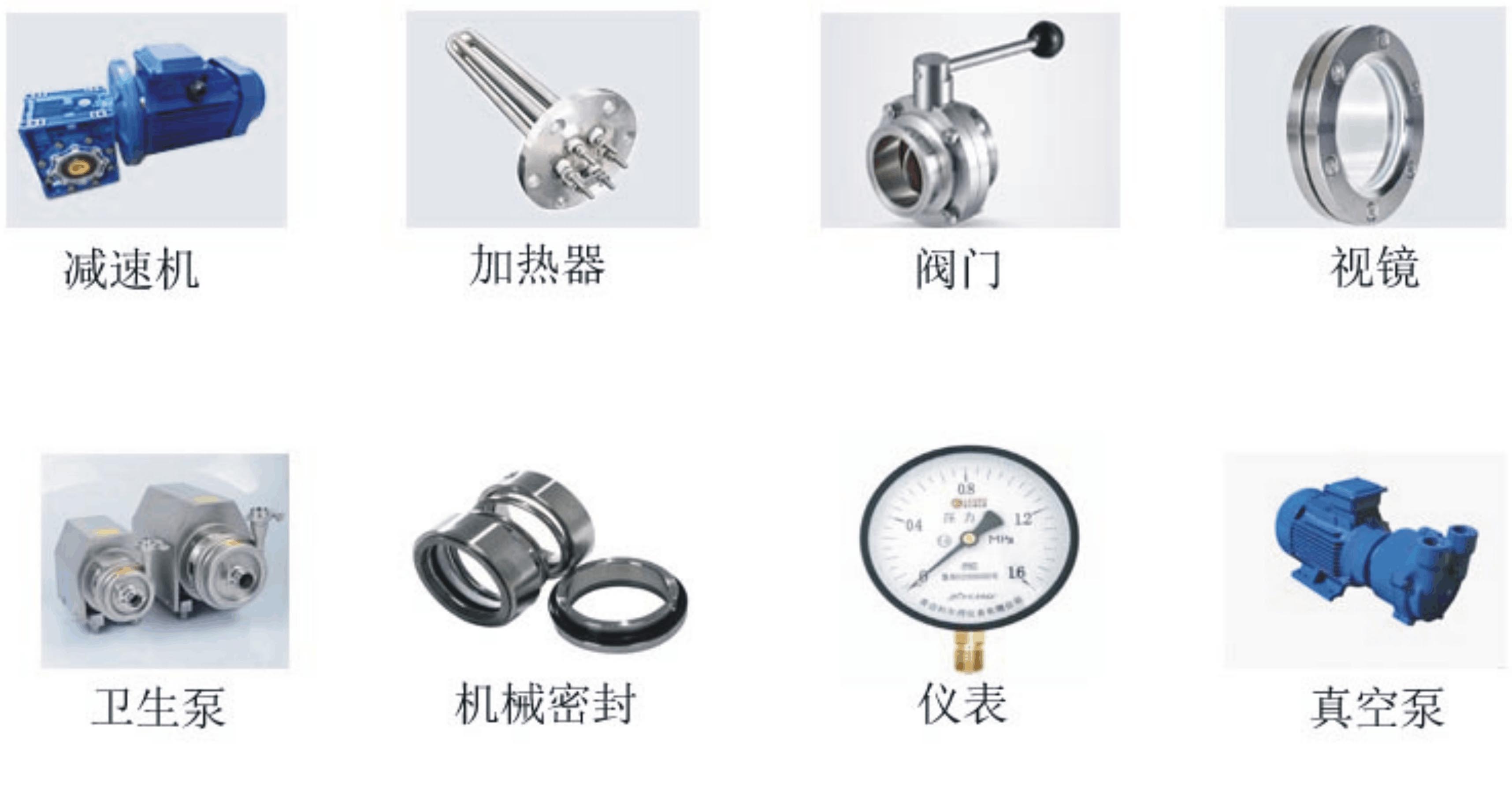

Note: The liquid storage tank can be designed as single-layer, double-layer (with insulation on the tank body and lower head), or jacketed (with a jacket and insulation on the tank body and lower head) based on customer requirements. It can adopt a vertical or horizontal structure and be customized into various shapes such as square or round, with optional mechanical stirring.

Here’s the English translation of the provided text, formatted for easy copying:

Can be used as a liquid storage tank, mixing tank, temporary storage tank, water storage tank, etc.

Applicable in fields such as food, dairy products, fruit juice beverages, pharmaceutical chemicals, and bioengineering.

Supports online CIP (Clean-in-Place).

The inner surface of the tank is mirror-polished, enabling CIP and SIP (Sterilize-in-Place), meeting sanitary standard requirements.

| Nominal Capacity | 300L | 400L | 500L | 600L | 800L | 1000L | 1500L | 2000L | 3000L |

|---|---|---|---|---|---|---|---|---|---|

| Cylinder Diameter (mm) | φ800 | φ800 | φ900 | φ1000 | φ1000 | φ1000 | φ1200 | φ1300 | φ1600 |

| Cylinder Height (mm) | 600 | 800 | 800 | 800 | 1000 | 1220 | 1220 | 1500 | 1500 |

| Working Pressure | ≤0.09Mpa | ||||||||

| Working Temperature | <100℃ | ||||||||

| Basic Configuration | Sanitary manhole, cleaning ball, liquid level gauge |

Note:

The tank parameters listed in the table are standard configurations and can be customized according to customer drawings and requirements.

Process parameters required for tank selection: material properties, working pressure, working temperature, special requirements, etc.

The liquid storage tank can be designed as single-layer, double-layer (with insulation on the tank body and lower head), or jacketed (with a jacket and insulation on the tank body and lower head) based on customer requirements. It can adopt a vertical or horizontal structure and be customized into various shapes such as square or round, with optional mechanical stirring and additional components.

Optional Stirring Available

Contact: Mr. Kingsley Ma

Phone: 13037600603

Tel: 0371-63752708

Email: [email protected]

Add: No. 316, Lianhua Street, Zhengzhou, Henan, China